The quaint town of Kingstree, nestled between the bustling cities of Charleston and Florence in Williamsburg County, South Carolina, is not just a picturesque locale; it’s also home to a bustling industrial scene. With approximately 3,200 residents, Kingstree boasts a landscape dotted with industrial and manufacturing facilities, contributing significantly to the town’s economic vitality.

Among these, a nutritional fatty acids manufacturer and a printing house stand out as major industrial dischargers, collectively constituting over half of the wastewater flow to the town’s treatment plant. However, this industrial boon posed challenges for the town’s wastewater treatment plant, particularly concerning effluent coliform bacteria and cyanide levels, which periodically exceeded NPDES permit limits. To tackle these issues head-on, the town embarked on a groundbreaking journey with us at Keck & Wood, exploring the potential of peracetic acid (PAA) as an alternative disinfectant to chlorine.

In this blog post, we delve into the journey of how Keck & Wood helped the town of Kingstree navigate the complexities of implementing PAA, from hypothesis to full-scale implementation, transforming wastewater disinfection in their wastewater treatment facility.

Enhancing Effluent Quality: Challenges and Solutions at Kingstree Wastewater Treatment Plant

The Kingstree wastewater treatment plant, with a capacity of 3.5 MGD, employs an oxidation ditch activated sludge process for secondary treatment. Despite its efficient design, the plant has grappled with persistent challenges in meeting NPDES permit limits, particularly concerning effluent coliform bacteria and cyanide. These hurdles stem from the substantial discharge of industrial wastewater to the Town’s facility, predominantly from two key contributors: a nutritional fatty acids manufacturer and a printing facility. Together, these industrial giants contribute over half of the influent flow to the plant, creating a significant impact on influent wastewater quality.

The plant’s struggle with effluent coliform violations can be attributed to the high chlorine demand of the industrial wastewaters. Similarly, cyanide violations likely arise from chemical reactions between chlorine disinfectant and compounds present in the high-strength industrial waste streams. Recognizing the urgency of the situation, the Town’s administration identified the imperative need for upgrading the disinfection system to address these persistent permit violations effectively.

Embracing Innovation: Exploring Peracetic Acid for Wastewater Treatment

Peracetic acid, commonly referred to as PAA, emerges as a promising disinfectant for wastewater treatment applications, offering a plethora of advantages over traditional methods. Formed by the reaction of acetic acid and hydrogen peroxide in water, PAA presents a paradigm shift in chemical disinfection practices.

Diverging from chlorine gas, which has long served as the conventional choice for wastewater disinfection, PAA introduces a host of benefits. Firstly, it sidesteps the production of carcinogenic disinfection byproducts associated with chlorine, thereby ensuring a safer and environmentally friendly treatment process. Moreover, its elevated oxidation potential allows for the utilization of lower doses to achieve comparable disinfection efficacy. This stark contrast is exemplified by the substantial reduction in dosage requirements at Kingstree —from over 30 mg/L of chlorine to 7 mg/L of PAA for this project.

One of the most notable advantages of PAA is its exemption from the need for dechlorination, even at residual levels below 1 mg/L, underscoring its minimal environmental footprint. Additionally, its safer handling protocols alleviate the necessity for elaborate risk management plans and containment infrastructure that may be required for chlorine gas, further streamlining operational requirements and procedures.

Moreover, PAA addresses a critical concern for this project — eliminating cyanide formation, a consequence often exacerbated by high chlorine dosing. By addressing this issue, PAA contributes to the overall improvement of effluent quality, aligning with regulatory standards and environmental stewardship goals.

Although PAA has been a stalwart in wastewater disinfection across Europe for over three decades, its adoption in the United States is relatively nascent. Historically employed in medical facilities and food processing plants, PAA’s efficacy lies in its ability to dissociate into hydrogen peroxide and acetic acid, facilitating the production of hydroxyl radicals that catalyze rapid and effective disinfection.

As wastewater treatment facilities seek sustainable and innovative solutions to address evolving challenges, the integration of PAA may stand at the forefront of transformative change, potentially promising enhanced efficacy, safety, and environmental stewardship in the realm of wastewater disinfection.

Investigating Peracetic Acid: A Hypothesis-Driven Approach

In embarking on the journey towards adopting peracetic acid (PAA) for wastewater disinfection, Keck & Wood formulated a series of hypotheses, guided by the overarching goals of enhancing effluent quality and achieving cost efficiencies:

- Elimination of Cyanide Exceedances: With periodic spikes in cyanide (CN) levels detected in the effluent, likely attributed to the high chlorine dosages that were required due to industrial contributors, we aimed to mitigate this issue through the implementation of PAA. The hypothesis posited that PAA would not generate cyanide compared to chlorine gas disinfection, thereby ensuring regulatory compliance and environmental protection.

- Reduction of Coliform Exceedances: In response to intermittent coliform exceedances in the effluent, we envisioned PAA as a potential solution to more efficiently reduce coliform contamination compared to chlorine. By leveraging PAA’s superior disinfection capabilities, the hypothesis aimed to establish a robust and consistent disinfection regime, safeguarding public health and environmental integrity.

- Achievement of Cost Savings: Confronted with high chlorine dosages exceeding 30 mg/L for adequate disinfection, we sought to capitalize on PAA’s higher oxidation potential. The hypothesis postulated that lower PAA doses could achieve comparable disinfection efficacy, resulting in substantial chemical cost savings compared to sodium hypochlorite.

To rigorously test these hypotheses, Keck & Wood devised a comprehensive testing plan encompassing bench, side-stream, and full-scale studies with the approval of the South Carolina Department of Health and Environmental Control (SCDHEC). By subjecting PAA to meticulous scrutiny across these stages, we aimed to conclusively demonstrate its effectiveness in addressing cyanide and coliform exceedances while simultaneously identifying cost efficiencies. This hypothesis-driven approach underscores our commitment to evidence-based decision-making and sustainable wastewater management practices, laying the foundation for informed and impactful implementation strategies.

Navigating Regulatory Pathways: SCDHEC’s Approval Protocol

The South Carolina Department of Health and Environmental Control (SCDHEC) administers the approval process for new disinfectants, such as peracetic acid, intended for wastewater treatment plants. The regulatory pathway for this project mandated the completion of three pivotal stages: bench, side-stream, and full-scale studies, ensuring comprehensive evaluation and validation of the PAA’s efficacy and safety.

- Bench Studies: The initial phase entails laboratory-based bench studies, where the efficacy of peracetic acid on wastewater samples is scrutinized. Parameters including disinfectant dose, contact time, temperature, and pH undergo rigorous assessment to delineate optimal conditions for disinfection. These studies serve as a foundational step in gauging peracetic acid’s effectiveness in controlled settings.

- Side-stream Study: Subsequent to bench testing, a Side-stream study is conducted directly at the wastewater plant. This phase involves dosing a side stream of the plant’s effluent with peracetic acid, employing temporary equipment. Over a span of five days, PAA underwent evaluation under real-world conditions, with routine sampling and testing conducted to monitor for coliform bacteria and other contaminants. This real-time assessment offered invaluable insights into peracetic acid’s performance in practical applications.

- Full-Scale Study: The final stage encompasses a comprehensive full-scale study lasting 30 days. Here, the entire plant flow was subjected to disinfection with peracetic acid, utilizing termporary equipment and infrastructure. The study monitored treatment efficacy, toxicity, and operational factors associated with employing peracetic acid as the primary disinfectant. This exhaustive evaluation culminated in a thorough assessment of peracetic acid’s suitability for permanent, full scale implementation.

By requiring this staged testing procedure, SCDHEC ensured a rigorous evaluation of peracetic acid’s capabilities, ensuring its efficacy and reliability in treating wastewater to meet stringent permit requirements. This scrutiny underscored SCDHEC’s commitment to safeguarding public health and environmental integrity, paving the way for informed decision-making and sustainable wastewater management practices.

Assessing Feasibility: Side-Stream Study for Peracetic Acid Implementation

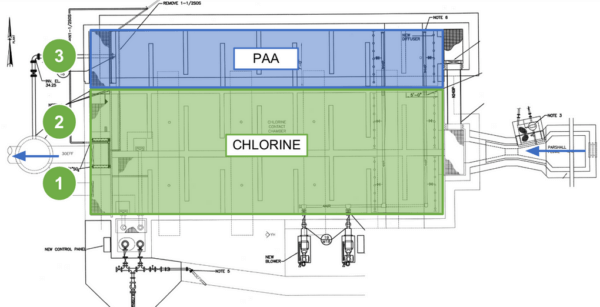

As a prerequisite for approving the full-scale implementation of peracetic acid (PAA), the South Carolina Department of Health and Environmental Control (SCDHEC) approved a rigorous 5-day side-stream study. This pivotal study involved the introduction of PAA into a side stream of the plant’s effluent, utilizing a portion of the chlorine contact chamber to isolate the disinfection process.

The study included:

- Duration: A concise 5-day timeframe was designated for the study, ensuring prompt evaluation of PAA’s efficacy.

- Environmental Compliance: Strident measures were taken to prevent any discharge to the environment, maintaining strict adherence to environmental regulations.

- Dosage Regimen: PAA dosing commenced at 8 ppm on the first day, progressively reducing by 1 ppm each subsequent day. This systematic approach enabled the assessment of PAA’s effectiveness across varying dosage levels.

- Sampling and Testing: Daily sampling and testing protocols were instituted to meticulously monitor disinfection efficacy and residual PAA concentrations.

- Residual Maintenance: Stringent measures were implemented to ensure the maintenance of a PAA residual between 0.5 – 1 ppm, optimizing disinfection outcomes while minimizing chemical usage.

The outcomes of the side-stream study yielded highly positive results. Notably, PAA dosing exceeding 5 ppm demonstrated zero NPDES permit exceedances over the entire 5-day period. A solitary coliform exceedance was observed at the 4 ppm PAA dose, highlighting the efficacy of PAA in mitigating microbial contaminants. Significantly, the study underscored PAA’s capacity to achieve robust disinfection outcomes at substantially lower doses compared to the previously employed chlorine dosage regimen that exceeded 30 ppm.

This compelling validation of PAA’s efficacy paved the way for advancing towards full-scale implementation, heralding a paradigm shift in wastewater treatment practices at Kingstree.

Validating Viability: Full-Scale Study of Peracetic Acid Disinfection

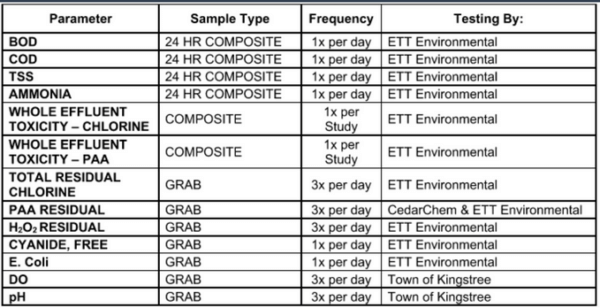

Conducting a comprehensive 30-day examination, the full-scale study marked a pivotal milestone in evaluating the efficacy and viability of peracetic acid (PAA) as the primary disinfectant at Kingstree’s wastewater treatment plant. The study encompassed the treatment of the entire plant flow with PAA, subjecting it to rigorous testing protocols to ascertain its efficacy and safety.

The requirements for the full-scale study comprised:

- Extended Trial Period: Spanning over 30 days, the trial provided ample time for thorough evaluation of PAA’s performance under real-world conditions.

- Continuous Monitoring: Testing was conducted throughout the study period, including tiered testing each week, whole effluent toxicity assessments for the initial 5 days, and Corbicula studies conducted weekly.

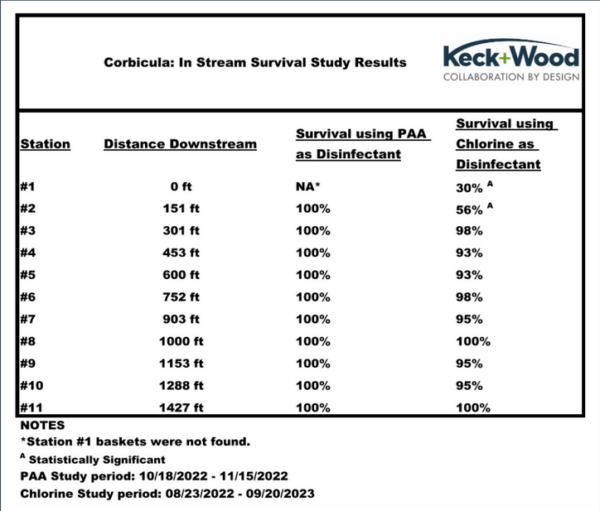

- Corbicula Study: Running in parallel with the full-scale study, the Corbicula study compared baseline chlorine disinfection with determinate PAA disinfection. Notably, while baseline chlorine disinfection exhibited significant mortality at both 0-ft and 150-ft, PAA disinfection showed no significant mortality, underscoring the difference in outcomes between PAA and chlorine.

Key findings from the full-scale study included:

- Targeted Dosing: PAA dosing was tailored with adjustments made to achieve a target residual of 0.5 mg/L PAA.

- Favorable Toxicity Testing: Results from whole effluent toxicity testing yielded favorable outcomes, further validating PAA’s safety and efficacy in treating wastewater.

- Positive Corbicula Study Results: The Corbicula study corroborated PAA’s superiority, demonstrating its ability to mitigate environmental impacts, as compared to chlorine.

- Regulatory Compliance: Throughout the study duration, coliform and cyanide levels remained below regulatory limits, affirming PAA’s capability to achieve disinfection requirements while adhering to stringent regulatory standards.

In summation, the full-scale study provided compelling evidence supporting PAA as a viable alternative to chlorine gas disinfection at Kingstree’s wastewater treatment plant. By effectively addressing disinfection requirements while maintaining regulatory compliance for coliform, cyanide, and toxicity, PAA emerged as a transformative solution for the Town of Kingstree.

Validating Hypotheses: Comprehensive Study Results

The culmination of the bench, side-stream, and full-scale studies provided confirmation of our hypotheses, showcasing peracetic acid (PAA) as an effective solution for wastewater disinfection. With a resounding affirmation, PAA emerged as a pivotal solution, effectively eliminating cyanide and coliform exceedances, thereby obviating NPDES permit violations throughout the studies.

The side-stream study served as a harbinger of PAA’s efficacy, demonstrating that a modest dosage of 5 ppm consistently achieved the targeted 0.5 ppm residual, while concurrently eradicating coliform and cyanide exceedances over the concise 5-day duration.

Further validation ensued during the full-scale 30-day trial, wherein PAA demonstrated its prowess in maintaining regulatory compliance, with cyanide levels remaining below 0.013 mg/L throughout the study. Despite encountering two isolated coliform exceedances attributed to operational glitches, PAA showcased resilience, underscoring its efficacy even at significantly lower dosages compared to chlorine gas.

Additionally, the favorable outcomes of whole effluent toxicity tests and the Corbicula study further bolstered PAA’s credentials, affirming its safety and environmental compatibility.

In summation, the study results underscored PAA’s status as a viable alternative to chlorine gas for disinfection at Kingstree’s wastewater treatment plant. Not only did PAA achieve improved permit compliance and eliminate the need for dechlorination, but it also required substantially lower doses compared to chlorine gas, heralding a paradigm shift in wastewater treatment practices towards more sustainable and efficient solutions.

Advancing Efficiency: Implementing Peracetic Acid Disinfection with Flow Pacing

In response to the dynamic disinfection demand at the Kingstree wastewater treatment plant, our team proactively proposed the implementation of flow pacing—an approach aimed at optimizing peracetic acid (PAA) dosing in real time.

Flow pacing entails flow-pacing the chemical feed pumps with the influent flow rate, ensuring a consistent disinfectant residual despite fluctuations in flow. This strategy not only enhances disinfection efficacy but also minimizes chemical costs by precisely matching dosage requirements to actual demand.

Our proposed solution involves the installation of new variable frequency drives (VFDs) on the peracetic acid feed pumps. These VFDs would interface with the plant’s Supervisory Control and Data Acquisition (SCADA) system, leveraging flow meters to continuously monitor influent flow rates. As flow rates fluctuate, the SCADA system dynamically adjusts the speed of the pumps, ensuring optimal PAA dosing tailored to prevailing conditions.

By implementing flow pacing, the Kingstree plant can effectively navigate the challenges posed by variable industrial flows, maximizing disinfection efficacy while minimizing chemical usage and associated costs. This cost-effective solution not only addresses immediate operational needs but also lays the groundwork for sustainable and efficient wastewater treatment practices.

Having finalized our recommendation, we have submitted a construction permit application detailing our proposal to the South Carolina Department of Health and Environmental Control (SCDHEC). We are currently awaiting SCDHEC approval so that bidding and construction of the project can begin. Our team at Keck & Wood stands ready to provide ongoing support, ensuring the successful integration of peracetic acid disinfection with flow pacing and further enhancing operational efficiency at the Kingstree wastewater treatment plant.

Project Team

Presenter

- Paul Smith III, P.E.

Staff Engineers

- Austin Lewandowski, P.E.

- Eric Vogt, P.E.

Our dedicated team of professionals has been instrumental in driving forward this project, offering expertise, insight, and support at every stage of implementation.

Leave A Comment